Why Robots Will Multiply in the Warehouse

The impact of the pandemic on the warehouse industry will have long lasting effects on the industrial sector. From concerns of worker safety to the rush to keep up with the surge in e-commerce orders, the need for increased warehouse automation became evident.

Viewed initially as “early adopter” technologies only affordable to e-commerce giants, robotics are now considered mainstream and are expected to grow in use and popularity. Technology continues to improve and costs have come down making robotics and other automation systems in scope even for smaller and middle market companies.

The Extra Mile

Even before e-commerce’s recent surge, working in a warehouse has long been physically demanding work. In certain warehousing operations, it is not unusual for workers to walk miles per day picking products. Labor productivity is a big focus in warehousing operations which is why “goods-to-person” automation systems make sense.

By 2023, it’s expected demand will quadruple for these systems. One of the reasons: order pickers frequently spend 70-75% of their time traveling. A goods-to-person system can reduce or eliminate that travel, allowing the person to focus 100% of their time on the productive work, and with a properly implemented goods-to-person system, productivity can triple, allowing one person to do the work of three.

The growth of e-commerce has put increased pressure on labor. Today, direct-to-consumer fulfillment operations can require up to 10 times as many employees to individually pick, pack and ship goods. Attracting and retaining qualified workers remains one of the biggest supply chain challenges.

A study last year by Auburn University found that 80% of supply chain professionals considered attracting and retaining labor as a top priority issue. Warehouse wages are increasing, too. For some companies, robotic solutions could offer a better return on investment.

Need for Speed

Millennials are the least patient when it comes to impediments to speed compared to their generational counterparts. Sixty-five percent of them say that long wait times for pick up or delivery negatively impacted their shopping experience, according to a consumer survey by Big Red Rooster, a brand experience company owned by real-estate services firm Jones Lang LaSalle Inc. (JLL).

By 2030, next-day and same-day fulfillment will be the dominant customer requirement, said 80% of the Auburn University survey respondents. The online grocery segment too is scaling to deliver in hours. Online grocery has been one of the fastest growing segments of e-commerce and is anticipated to grow to $100 billion in sales by 2022 according to the Food Industry Association (FMI). Proof of this demand is also reflected as Kroger Co.’s fourth quarter digital sales grew 118%, according to a report by JLL.

Kroger and Britain’s Ocado Group Plc, which opened the first of up to 20 fully automated fulfillment centers in April 2021, will use artificial intelligence, robots with totes and a proprietary control system to pick and pack deliveries. The adoption of robotics and automation systems could help make these consumer expectations a reality.

Reducing Risk

Providing for an employee’s well-being, especially in a fast-paced, competitive distribution environment, is a critical success factor. Workers face a greater risk of injury when they are tired from working long hours, or continually doing repetitive and physically demanding tasks. Not surprisingly, these activities are exactly what robots excel at and desire.

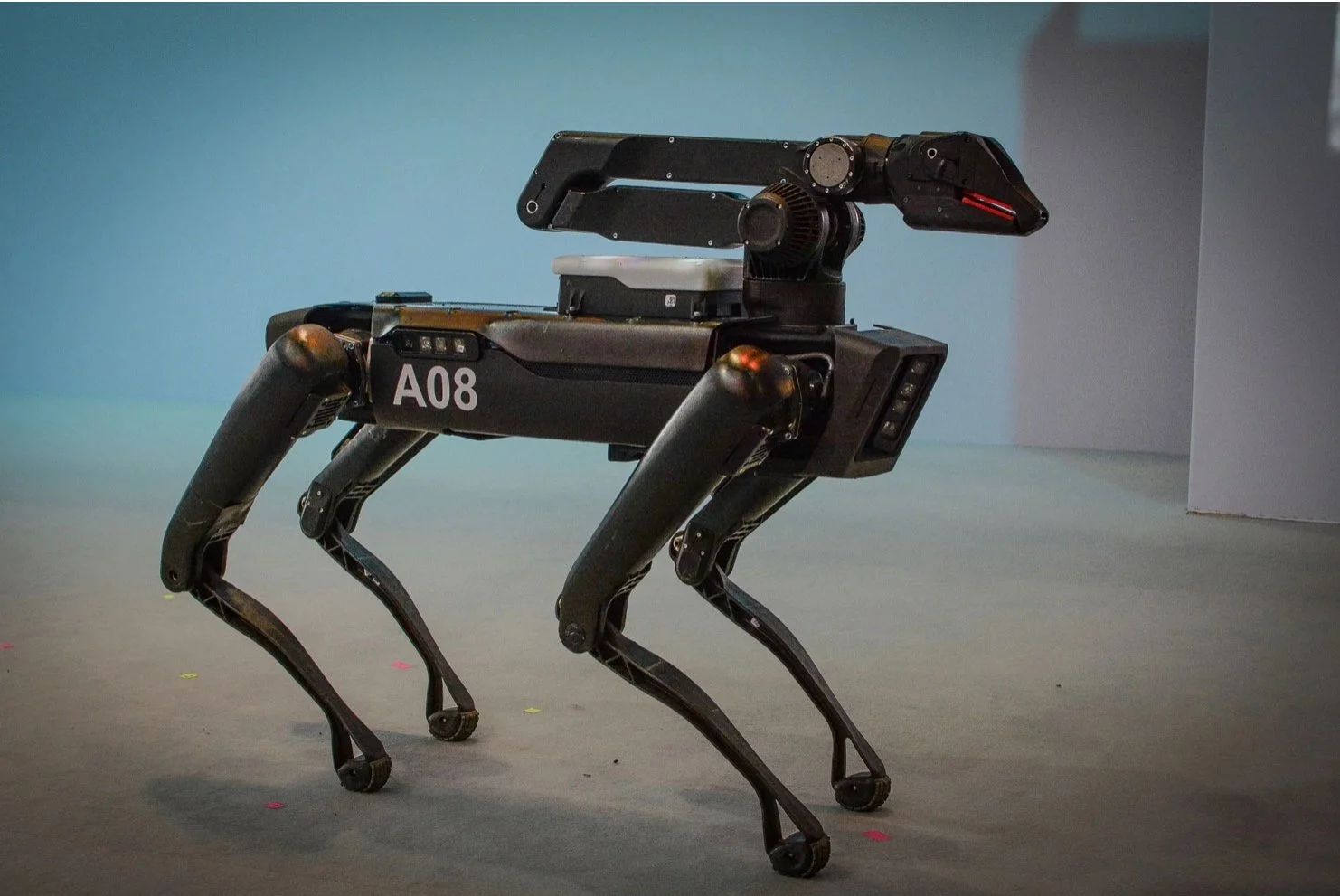

Robotics company Boston Dynamics has created a machine called “Stretch,” which is capable of moving 800 boxes per hour in the warehouse and can potentially be used to unload trucks, strip cases off pallets, and transfer cartons to conveyors. This was driven by the need to manage high-speed operations as well as mitigate the increasing cost of labor.

Eighty percent of supply chain professionals expect greater investments in automation by their companies in the next 10 years, and 88% say they’ll be more reliant on automation and robotics in the nearer future.

New technology and demographics continue to transform the industry, pushing expectations to new levels. From a supply chain perspective, the global pandemic put a huge spotlight on risk management with a special emphasis on people. When it comes to labor, although robotics and automation will never eliminate the need for qualified employees, it certainly can help mitigate the risk.